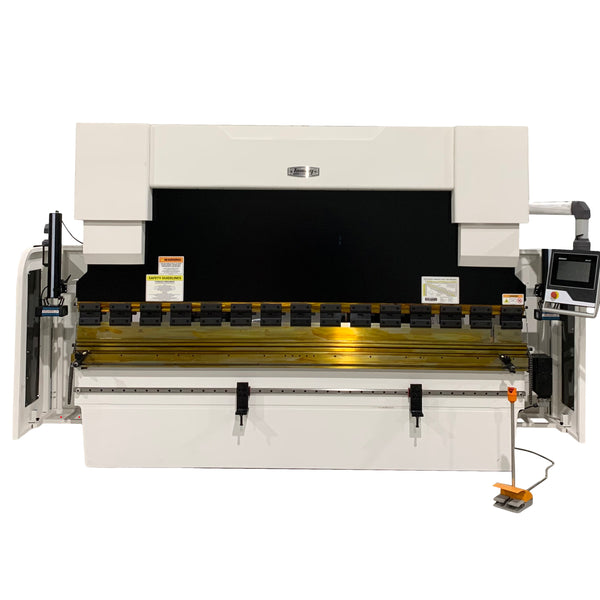

Tommy Industrial® hydraulic press brakes provide exceptional performance by utilizing high quality components, resulting in a precise machine that delivers accurate bends time and time again.

All Tommy Industrial® press brakes start out as base machines that include many standard features as listed below. However, we understand that some customers may require a more advanced press brake; that’s why we offer many advanced controller systems and machine options that will meet and exceed your needs, surpass expectations, and meet your budget.

When manufacturing our Tommy Industrial® press brakes, we only use the best steel and components available, some brand name components included are:

STANDARD EQUIPMENT ON ALL Tommy Industrial® Press Brakes includes:

AVAILABLE CONTROL SYSTEM OPTIONS:

OTHER AVAILABLE OPTIONS:

Note: This Tommy Industrial® press brake includes a general-purpose goose-neck punch and multi-opening die. The included general-purpose goose-neck punch and multi-opening die are for training purposes only. There is no warranty on these items. End user should purchase tooling to meet their unique needs and specifications.

| Item | Imperial | Metric | |

|---|---|---|---|

| Working area | Pressure force | 401 ton | 4000 kN |

| Brake length | 236 in | 6000 mm | |

| Distance between columns | 201 in | 5100 mm | |

| Throat | 16 in | 400 mm | |

| Clear opening | 25 in | 630 mm | |

| Bending speed | |||

| Rapid feed | |||

| Return speed | |||

| Drive capacity | Motor rating main drive | 40 hp | 30 kW |

| Measures and weights | Hydraulic tank volume | ||

| Overall dimensions (length x width x height) | 240x104x146 | 6100x2650x3700mm | |

| Weight | |||

This page has answers to the most common questions regarding product warranty, replacement parts, payment options, leasing, our locations, and in-house demos.

If you have questions on order fulfillment and logistics please see Shipping & Handling FAQs.

Jump to a section:All of our machines come with a one-year limited warranty. Please click here to see the details.

Also included with all Tommy Industrial® products is a lifetime of free technical support and advice from our many machine experts. Our in house machine experts have real life metal working experience.

Back to TopYes, we carry the most common replacement parts for all machines in stock. In the rare event we do not have the part requested in stock, we will have it shortly.

Back to TopWe accept the following forms of payment for orders of $3,000.00 and under.

For orders greater than $3,000.00 we accept:

Yes you can! We have an aggressive finance team that works for you! To learn more see our Leasing & Financing

Back to TopTommy Industrial® products are made in manufacturing plants all over the world. Some of the factories are located in the USA, Portugal, Italy, Poland, England, Germany, China, France and Taiwan.

Back to TopContact us to arrange for a demonstration of our equipment, we will set up the machines to work on the material used in your application.

Back to TopTommy Industrial® works hard to arrange timely intact and economical shipping for our customers. We work with many different shipping companies to ensure the best price for the shipment and pass those savings on to you.

You can also arrange your own shipping, when applicable, if you’d prefer. Talk to a customer service representative at 1-844-895-3316 for more information on this option.

Tommy Industrial® ships items weighing less than 100 lbs. via UPS Ground. We ship items that weigh more than 100 lbs. or oversized items as truck freight. In this case, your delivery address must be accessible by tractor-trailer.

Truck drivers are not required to assist with unloading. You are responsible for unloading freight and for moving it into your shop. For shops without a loading dock, liftgate delivery is available for an additional charge.

For details, call and talk to a customer service representative 1-844-895-3316.

You can also arrange to pick up your freight at the carrier's terminal. The carrier will load the item onto your vehicle. If you choose this option, please make sure your vehicle is capable of handling the weight and bring plenty of tie-downs to secure the load properly.

Ground Shipments (up to 100 lbs.)

Typically within 24 hours. Once processed, ground shipments that are in stock will usually leave our facility in a day or less.

Freight Shipments and Covid-19 (more than 100 lbs.)

Once processed, freight shipments that are in stock will usually leave our facility within 5 to 20 business days. Please be advised that the Covid-19 Pandemic has led to shipping surges, this means that sometimes carriers are at capacity and will often not be able to pick up and or deliver shipments as scheduled.

To find out how long your order will take to arrive, please call us at 1-844-895-3316 and ask what the shipping delay will be.

Tommy Industrial® works with several different shipping companies to ensure the best price for the shipment, and we pass those savings on to you.

No, we cannot expedite the inspection, testing, and packaging portion of the lead time. However, we do have ways to shorten the delivery period of the shipment. Talk to a customer service representative at 1-844-895-3316 for more information.

Not a problem! Call 1-844-895-3316 and ask a customer service representative for information about your options.

Yes, we do. Please call a Tommy Industrial® representative at 1-844-895-3316 for an updated freight quote.

We use FOB Origin for all shipments, which means that you are responsible for the merchandise from the time of purchase.

IRONWORKER LLC TERMS AND CONDITIONS OF SALE

These terms and conditions shall apply to all orders entered into by and between any distributor or any end-user of the Goods, whichever the case may be (“Buyer”) and IRONWORKER LLC. (“Seller”). These terms and conditions and any Seller quotation form submitted herewith or separately shall be collectively referred to hereinafter as the “Agreement.” Seller shall accept orders, sell Goods, and do business only upon these terms and conditions. Any additional or different terms in Buyer’s purchase order or other purchase documentation are deemed material alterations to this Agreement, and Seller hereby gives notice of its objection to them. The term “Goods” means all items sold and/or provided by Seller to Buyer, whether goods, materials, products to be manufactured and delivered, services to be rendered, or any combination thereof.

Price. If any price quotation is stated on the face hereof, such price quotation shall be good only for a period of thirty (30) days from the date of such quote. Thereafter, the price for Goods sold hereunder shall be the Seller’s price in effect as of the date of shipment. All prices are F.O.B., the Seller’s plant of manufacture, unless otherwise stated. If any price quotation includes delivery, freight charges or import tariffs, of any kind, the customer is liable for any amount that exceeds the quoted amount. If the actual delivery, freight charges or import tariffs, of any kind are less than the quoted amount, the proceeds are deemed earned.

If any tariffs, duties, or similar government-imposed costs are introduced or increased after the date of quotation, Buyer agrees that the additional costs will be added to the purchase price and must be paid by Buyer".

The buyer agrees to pay any additional costs due to tariffs or other government-imposed costs, as calculated by seller.

Prices also do not include any federal, state, or local taxes or other governmental charges upon or with respect to the sale, purchase, manufacture, delivery, storage, processing, use, or consumption of any of the Goods provided hereby. Prices are stated and payable in U.S. dollars.

Cancellation. Buyer may not suspend or cancel orders placed with Seller, except with Seller’s prior written consent and then only if Buyer reimburses Seller for all losses incurred due to such suspension or cancellation, including without limitation, all incidental and consequential damages and expenses arising therefrom. Direction from Buyer to suspend or cancel any order may be treated as repudiation, making Buyer immediately liable for loss, expense and other damages sustained.

Delivery. Title to and risk of loss for the Goods shall pass to Buyer upon delivery of the Goods by Seller to the common carrier for delivery. If Buyer does not specify shipping instructions, Buyer hereby authorizes Seller to make shipping arrangements on Buyer’s behalf and Buyer shall be responsible for all costs and expenses associated therewith. All timeframes provided by Seller, whether verbally or in writing, are good faith estimates of the expected delivery date for the Goods. Seller shall use commercially reasonable efforts to fill Buyer’s orders within the time stated but in no event shall Seller be liable for any damages associated with Seller’s inability to meet any such timeframes or deadlines, including but not limited to incidental or consequential damages arising therefrom.

Inspection & Acceptance. Buyer shall inspect all Goods within five (5) days after receipt thereof. Buyer’s payment shall constitute final acceptance of the Goods and shall act as a waiver of the Buyer’s rights to inspect or reject the goods unless otherwise agreed. If Buyer rejects any merchandise, Buyer must first obtain a Returned Goods Authorization (“RGA”) Number before returning any goods to Seller. Goods returned without a RGA will be refused. Seller will not be responsible for any freight costs, damages to goods, or any other costs or liabilities pertaining to goods returned without a RGA. Seller shall have the right to substitute a conforming tender. Buyer will be responsible for all freight costs to and from Buyer and repackaging costs, if any, if Buyer refuses to accept shipment. If Goods are returned in unsalable condition, Buyer shall be responsible for full value of the Goods. Buyer may not return any special order Goods. Any Goods returned hereunder shall be subject to a restocking fee equal to 35% of the invoice price.

Limited Warranty. Seller warrants to the original end-user that the Goods manufactured or provided by Seller under this Agreement shall be free of defects in material or workmanship for a period of twelve (12) months from the date of purchase, provided that the Goods are installed, used, and maintained in accordance with any instruction manual or technical guidelines provided by the Seller or supplied with the Goods, if applicable. The original end-user must give written notice to Seller of any suspected defect in the Goods prior to the expiration of the warranty period. The original end-user must also obtain a RGA from Seller prior to returning any Goods to Seller for warranty service under this paragraph. Seller will not accept any responsibility for Goods returned without a RGA. The original end-user shall be responsible for all costs and expenses associated with returning the Goods to Seller for warranty service. In the event of a defect, Seller, at its sole option, shall repair or replace the defective Goods or refund to the original end-user the purchase price for such defective Goods. Goods are not eligible for replacement or return after a period of 30 days from date of receipt. The foregoing warranty is Seller’s sole obligation, and the original end-user’s exclusive remedy, with regard to any defective Goods. This limited warranty does not apply to: (a) die sets, tooling, and saw blades; (b) periodic or routine maintenance and setup, (c) repair or replacement of the Goods due to normal wear and tear, (d) defects or damage to the Goods resulting from misuse, abuse, neglect, or accidents, (f) defects or damage to the Goods resulting from improper or unauthorized alterations, modifications, or changes; and (f) any Goods that has not been installed and/or maintained in accordance with the instruction manual or technical guidelines provided by Seller.

EXCLUSION OF OTHER WARRANTIES. THE FOREGOING LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. ANY AND ALL OTHER EXPRESS, STATUTORY OR IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE ARE EXPRESSLY DISCLAIMED. NO WARRANTY IS MADE WHICH EXTENDS BEYOND THAT WHICH IS EXPRESSLY CONTAINED HEREIN.

LIMITATION OF LIABILITY. IN NO EVENT SHALL SELLER BE LIABLE TO BUYER OR ANY OTHER PARTY FOR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES (INCLUDING, WITHOUT LIMITATION, LOST PROFITS OR DOWN TIME) ARISING FROM OR IN MANNER CONNECTED WITH THE GOODS, ANY BREACH BY SELLER OR ITS AGENTS OF THIS AGREEMENT, OR ANY OTHER CAUSE WHATSOEVER, WHETHER BASED ON CONTRACT, TORT OR ANY OTHER THEORY OF LIABILITY. BUYER’S REMEDY WITH RESPECT TO ANY CLAIM ARISING UNDER THIS AGREEMENT IS STRICTLY LIMITED TO NO MORE THAN THE AMOUNT PAID BY THE BUYER FOR THE GOODS.

Force Majuere. Seller shall not be responsible for any delay in the delivery of, or failure to deliver, Goods due to causes beyond Seller’s reasonable control including, without limitation, acts of God, acts of war or terrorism, enemy actions, hostilities, strikes, labor difficulties, embargoes, non-delivery or late delivery of materials, parts and equipment or transportation delays not caused by the fault of Seller, delays caused by civil authorities, governmental regulations or orders, fire, lightening, natural disasters or any other cause beyond Seller's reasonable control. In the event of any such delay, performance will be postponed by such length of time as may be reasonably necessary to compensate for the delay.

Specifications. Seller may, at its option, make changes in the designs, specifications or components of the Goods to improve the safety of such Goods, or if in Seller’s judgment, such changes will be beneficial to their operation or use. Buyer may not make any changes in the specifications for the Goods unless Seller approves of such changes in writing, in which event Seller may impose additional charges to implement such changes.

Installation. If Buyer purchases any Goods that require installation, Buyer shall, at its expense, make all arrangements and connections necessary to install and operate the Goods. Buyer shall install the Goods in accordance with any Seller instructions and shall indemnify Seller against any and all damages, demands, suits, causes of action, claims and expenses (including actual attorneys’ fees and costs) arising directly or indirectly out of Buyer’s failure to properly install the Goods.

Work By Others; Safety Devices. Unless agreed to in writing by Seller, Seller has no responsibility for labor or work performed by Buyer or others, of any nature, relating to design, manufacture, fabrication, use, installation or provision of Goods. Buyer is solely responsible for furnishing, and requiring its employees and customers to use all safety devices, guards and safe operating procedures required by law and/or as set forth in manuals and instruction sheets furnished by Seller. Buyer is responsible for consulting all operators’ manuals, ANSI or comparable safety standards, OSHA regulations and other sources of safety standards and regulations applicable to the use and operation of the Goods.

Remedies. Each of the rights and remedies of Seller under this Agreement is cumulative and in addition to any other or further remedies provided under this Agreement or at law or equity.

Attorney’s Fees. In the event legal action is necessary to recover monies due from Buyer or to enforce any provision of this Agreement, Buyer shall be liable to Seller for all costs and expenses associated therewith, including Seller’s actual attorneys' fees and costs.

Governing Law/Venue. This Agreement shall be construed and governed under the laws of the State of Wisconsin, without application of conflict of law principles. Each party agrees that all actions or proceedings arising out of or in connection with this Agreement shall be commenced, tried, and litigated only in the state courts sitting in Marathon County, Wisconsin or the U.S. Federal Court for the Western District of Wisconsin. Each party waives any right it may have to assert the doctrine of “forum non conveniens” or to object to venue to the extent that any proceeding is brought in accordance with this section. Each party consents to and waives any objection to the exercise of personal jurisdiction over it by courts described in this section. EACH PARTY WAIVES TO THE FULLEST EXTENT PERMITTED BY APPLICABLE LAW THE RIGHT TO A TRIAL BY JURY.

Summary of Return Policy.

· 5 Day acceptance period from date of delivery. Damage claims and order discrepancies will not be accepted after this time.

· You must obtain a IRONWORKER LLC issued RGA number PRIOR to returning any materials.

· Returned materials must be received at IRONWORKER LLC in new condition and in original packaging.

· Altered items are not eligible for return.

· Buyer is responsible for all shipping charges.

· A 35% re-stocking fee applies to all returns.

IRONWORKER LLC makes every effort to ensure that our posted specifications, images, pricing and product availability are as correct and timely as possible. We apologize for any discrepancies that may occur. IRONWORKER LLC reserves the right to make any and all changes deemed necessary in the course of business including but not limited to pricing, product specifications, quantities, and product availability.

For Customer Service & Technical Support: Please contact one of our knowledgeable Team Members at: 1-844-895-3316 or e-mail us at service@tommyindustrial.com